Edited by Lori Beckman, Senior Editor, Production Machining

Source: Jayco Cleaning Technologies

As the Environmental Protection Agency evaluates the impact of hazardous substances such as methylene chloride, perchloroethylene (PCE/PERC), n-propyl bromide (NPB), and trichloroethylene (TCE), manufacturers face the challenge of adapting their cleaning processes to meet evolving regulations. (Waterbury, Connecticut) and (West Chester, Ohio) have have collaborated to develop a solution for new regulatory changes.

With a combination of chemistry and the proper equipment, new cleaning regulations can be met, according to Mike Valenti, director of technology at ��������Ƶ. “It’s important that we talk about this as a process replacement and not just a chemical replacement,” he says.

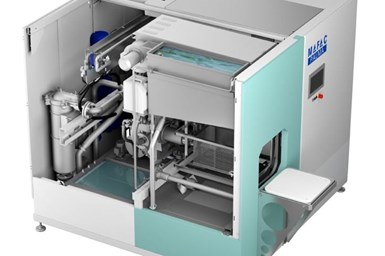

Aqueous single chamber vacuum cleaning systems by Jayco’s Mafac vacuum-assisted rotary basket parts washer, combine spray flood, ultrasonics, rotation and vacuum processes.

The big difference between aqueous and vacuum vapor degreasing processes is the temperature of the parts coming out of the equipment. With aqueous processes, parts are 94 – 95° F, and therefore cool enough for operators to handle those parts immediately. However, with the vacuum vapor degreasing processes, those parts are coming out very hot and require time to cool before they can move on through the process, slowing down throughput.

Regarding solvent, as the regulatory landscape shifts, solvent alternatives face increasing scrutiny and uncertainty. Aqueous cleaning solutions emerge as the safer and more sustainable choice, according to ��������Ƶ.

The company’s Aquaease PL 732 complements the mechanical and vacuum attributes of the Mafac parts washer, offering a residue-free solution. Its low foaming and free rinsing properties meet stringent industry standards set by Boeing material specifications.